The web server holding my earliest postings into an uncaring universe quietly expired a while ago. Rather than replacing it, I'm posting the content so it will live on forever in the cloud, polluting my little corner of it. Enjoy.

2.7 Engine Rebuild (part 2)

Where were we? Oh yeah, pulling greasy crap off and putting it in a bucket. This is how its done down in Charlotte at the NASCAR shops right?

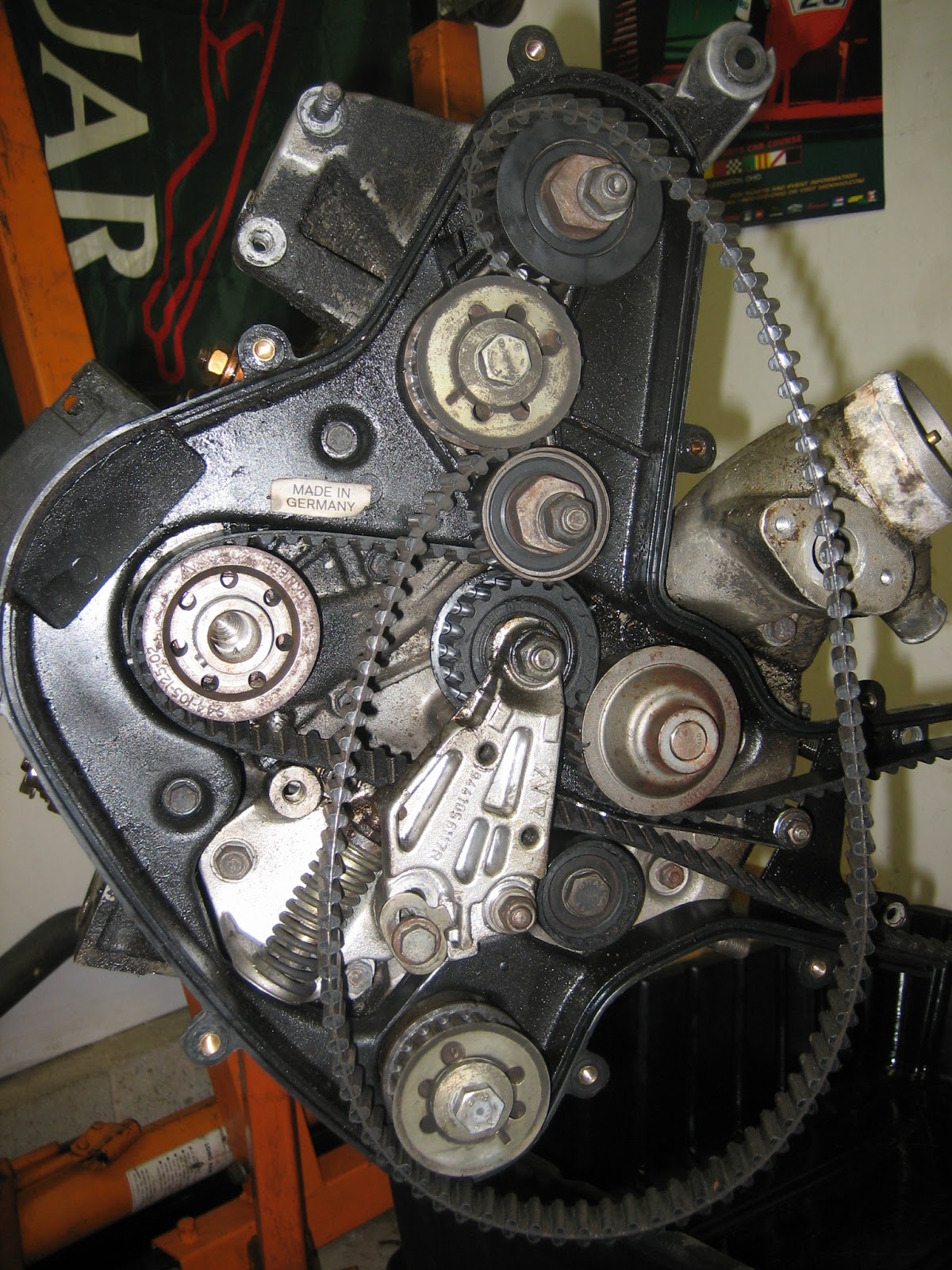

Here's the front of the motor. That sticker says "Made in Germany", so this must be a precision instrument.

A short while (and a few beers) later... belts and rollers gone, spring tensioner gone

Right side of the motor, practially nude. Oil pump gone, balance shaft cover gone (balance shaft shown in place just in case I forget where to replace it) Side of the motor clean enough to eat off of ... maybe not.

Here's an example on how I plan on putting the motor back. EVERY time I take something off, I take a picture, usually including my fat finger pointing at something of interest. Here I'm getting ready to pull the oil pump, so I'm pointing out to my future self Self, note there a washer AND a small round green seal here. Don't forget the seal!

You'll also notice the fine concours quality of the engine in this close-up. This is after 2 cans of engine degreaser and a wash down. That's why everything is going to the machine shop, for a good dunking in their acid bath.

Here's the bottom of the block with the crankshaft girdle removed. Starting to smell the horse in the barn or some such folksy American turn of phrase.

I'm starting to feel like a real race shop, I've got boxes of crap now.

The only thing left in the block is the crank. And it's days are numbered

Told ya!

The Naked Block in all its glory. Note the fine aged patina. Ah 89, that was a good year.

Everybody likes pictures, so here's another view. Naked cylinders, ooohhh.

This is another part of my master plan on having a motor that works when I'm done:

I put all the nuts and bolts, washers, gears, etc in plastic bags with a note inside. So when I go to bolt the oil pump back on, I know where the 46 bolts ( 5 different sizes) are. This method worked with my head gasket repair, so that's my story and I'm sticking to it.

So everything's apart. Lots of things are at the machine shop. The head and valves to be inspected and cleaned; block to be cleaned and bore diameters to be checked; pistons to be clean, inspected and rings replaced if needed. Crankshaft is having #2 & #3 rod areas cross-drilled to keep the rod bearings happy and balanced. Oil pan is having the Lindsey Racing baffle welded in - also to keep the rod bearings happy. Unhappy rod bearings = my race motor (see earlier pictures). And everything is taking a much needed bath

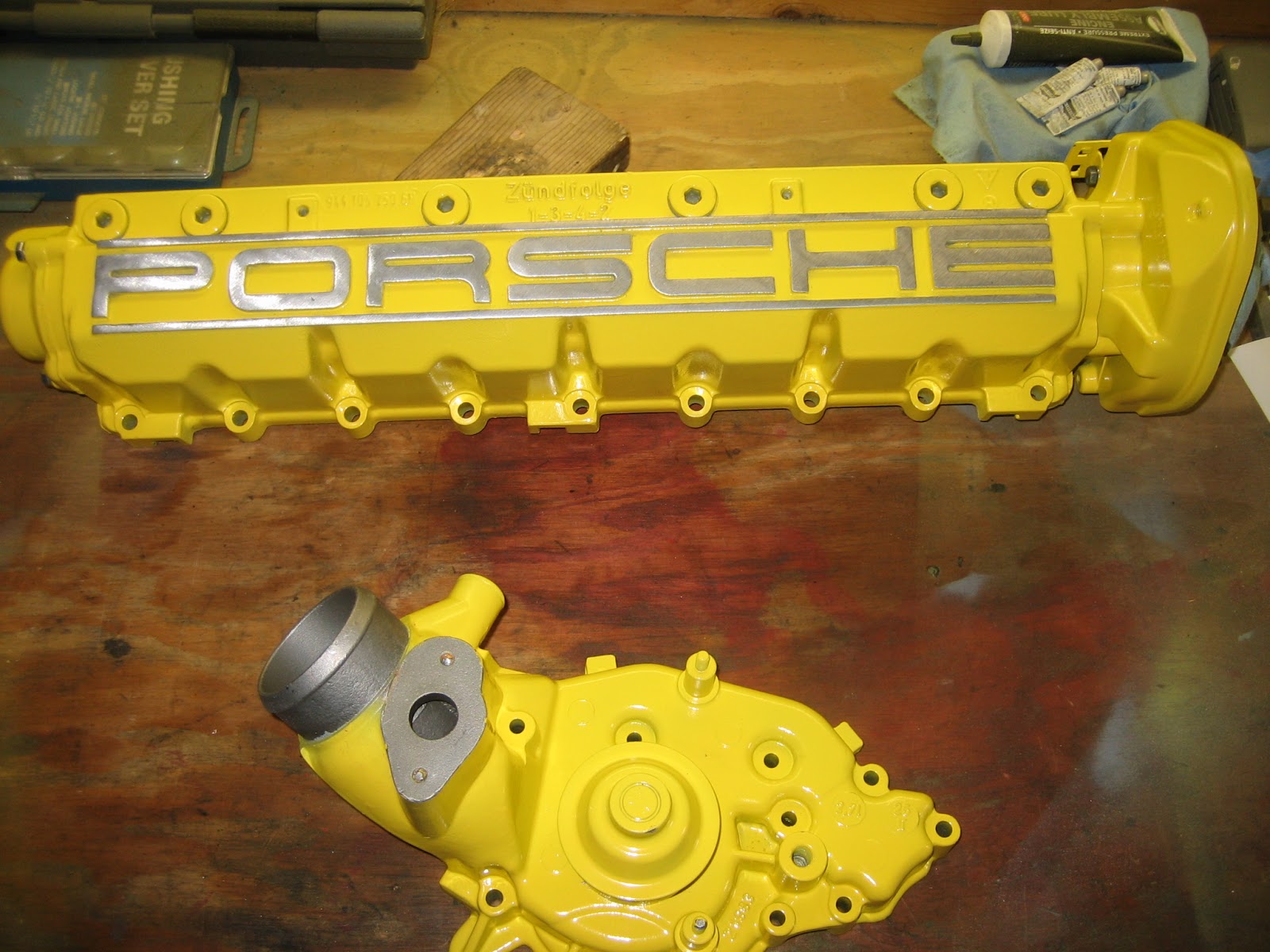

But you know what they say about idle hands .. since I'm waiting for machine shop I decided to provide some 'bling' to my motor, so I won't be embarrassed when I pop the hood at the local Porsche club events

My unsuspecting victim was the cam tower. And while I was in the middle of my blingfest my new waterpump innocently entered the Alpine garage. Too bad for it.

Assembly is the reverse of Dis-assembly right? More to come ...

Subscribe to:

Post Comments (Atom)

My (Premature) Obiturary

Lots of news organizations maintain pre-written obits so that when a celebrity passes, they open up the file and need to just update a few l...

-

Other than making zoom-zoom noises I'm a pretty useless motor When we last left off, I was young, full of unwarranted optimism, eager ...

-

Hanging out in a Yurt in Tibet with the Golok nomads. Drinking Barley Tea, heated by burning dried yak turds. Some temple details. This wa...

-

Nothing like suffering through the Philly Love Run Half Marathon and vowing never to do it again, and then signing up for another Half. Ye...

.jpg)

No comments:

Post a Comment