The web server holding my earliest postings into an uncaring universe quietly expired a while ago. Rather than replacing it, I'm posting the content so it will live on forever in the cloud, polluting my little corner of it. Enjoy.

2.7 Engine Rebuild (part 4)

Just a couple more steps to go before we can stuff it into the racecar.. I need to put in a new pilot bearing, attach the clutch and the bell housing.

The pilot bearing is one of those things you really wish you did when you had the chance. Because later, it's not fun trying to get to it. It was only $10, so what the hell.I didn't have the fancy tool for removing the pilot bearing, but a little backyard engineering came to the rescue. I took apart the bearing puller I did have, and it fit perfectly into the hole. And by camming it and smacking it with hammer while rotating, I was able to coax the bearing out.

Here's my nice new clutch attached to the flywheel. This was an unplanned ($$$) expense in the rebuild. While taking a good look at my current clutch I noticed that even though it had plenty of wear left - credit my smoooth clutching skillz - it was also dated 1993. Hmmm, seems a bit old. This is another case of where it would really suck if I was 800 miles from home, having dropped a huge amount, oh Hi Honey! - I meant an modest amount, on the race weekend and metal fatigue causes the clutch to die. I'm not doing a clutch in the paddock, so it's packing up and going home. So I ponied up the bucks for a new clutch. A few dollars now will save many down the road. At least that's my story

So Grasshopper, how can you tell when the engine is at TDC (Top Dead Center)?"

"Ah Master, there is an invisible mark on the flywheel. This is found in the back of the engine compartment that must be seen while lying atop the engine, while looking down through a tangle of wires and hoses, while peering through a tiny window upon the unseen wonders below. If you are truly "one with the car" you can see this mark with your eyes shut. But Master, I have not seen this "mark" and believe it is only a rumor told to children and the gullible."

Since I'm not a Zen master (and wear reading glasses also) I decided to help my future self. I painted a nice visible yellow stripe and marked the TDC mark. My future self thanked me yesterday.

Here's the aforementioned tiny window in the bellhousing. This is with the engine still out of the car so you don't get the full effect. But if it was in the car, I'd never be able to take a picture anyway. Too much stuff in the way. But you can see why my future self was giving me props for the yellow striping.

Here's another case of "while you're working on the car" ... Actually this was planned for the winter downtime. This was supposed to the "Major" winter time project - putting in a Limited Slip in the tranny. And not just any old limited slip, but a Guards Transmission race 80/50 LSD. Time to be bringing it to the big boys in 44Cup. Rebuilding the motor is cool and all, I'm learning lots about my car. But the Guards LSD ... Oh yeah, this I'm looking forward to on the track next year.

So the tranny got pulled and shipped off to a shop to put the Guards unit in.

While waiting for the clutch parts to show up, there was plenty more to be done before we can put the motor back in. Part of that included cleaning up the engine compartment from all that liquid smoke that escaped from the hole in the block. Many hours were spent scrubbing with mineral spirits. Also when we pulled the dead motor, we managed to snag the power steering return line (the steel line at the top of the cross-member) and pulled it out of its fitting. I had to cut off the fitting and reclamp it. We'll find out whether or not it leaks later..

Yeah, this brings back fond memories: pretzeled into contorted shapes, with various car bits poking me in private locations, inhaling toxic fumes while scrubbing away with my little toothbrush. You just can't buy fun like that in the store.

Before my engine let all the smoke out in the Summit race, it felt the need to distribute little metal bits throughout the oil cooling system in the car. Rather than attempting to clean my external oil cooler and maybe not getting all of those little bits out, I went and bought a new one. Hey, what's another $100? If you can't afford to get a home-equity loan to finance your hobby, you need to find another sport than racing. Don't blame me if we go into a recession in the coming months, I'm definitely doing my part to boost parts of the economy.

Finally, we're ready to go back on the horse that threw me. It's been a long 4 months to get to this point.

My partner in crime, Joel, is off making the world safe for something, probably visiting exotic places filled with sand, courtesty of his travel agent, the US Gov. So I had to put this puppy in by myself. I got pretty good at it, being I had to do it twice. The first time, I was all proud, admiring my work, the nice contrasting yellow against the bright red when I realized that I had forgotten to attach the headers. Doh!

Status Check: Here it's the end of February. The rebuilt motor is in the car, new clutch slave cylinder attached, all hoses and vacuum lines routed, fuel lines attached, electrical connections made, water, oil, fuel, power steering fluid and brake fluid all in the correct place. Gregg Wilson stopped by and helped me get the drive line attached. So, let's start her up.

After a minute or two of cranking with the DME and plugs pulled, my oil pressure came up. Yay!! first hurdle passed. The motor spins and can pump oil through all its little passages. Step 2: some spark. Now I'm holding my breath. Couple of cranks and it fires! Man does it sound like shit, backfiring like crazy. Quick turn it off! I'm sure my neighbors aren't appreciating the sound of a backfiring engine at 11pm. Especially not one with only the headers and no muffler attached. Time to call it a night and have beer.

The next day I do a little debugging and find that I swapped two of my plug wires and the speed sensors were too close to the ring gears, they were getting banged on. I pulled out the sensor and reset the clearance - another job just as much fun as detailing the engine compartment but without the enjoyable paint fumes. And after doing that, it doesn't start at all. Great.

Rumage thru the tools and find the multimeter. Hmm, seems one of the speed senors is bad according to Clarks Garage. So off to the internet and use my searching skills to score new overstock ones for $35 each. Sweet, but they won't be here until after the weekend. So, maybe I'll use this opportunity to put the tranny in... Nah, I'm gonna drink some Guiness and watch TiVo. Back next week.

Thursday, December 11, 2014

944 Racecar - 1st Engine Rebuild (part 3) Winter 2007-2008

The web server holding my earliest postings into an uncaring universe quietly expired a while ago. Rather than replacing it, I'm posting the content so it will live on forever in the cloud, polluting my little corner of it. Enjoy.

2.7 Engine Rebuild (part 3)

Assembly is the reverse of Dis-assembly right? At least that's the conventional wisdom, but I'm not sold on that. You try making beer out of urine ....

Building a motor is a lot of work, so before we get started, let's take a break and take a look at why I'm (other than insanity) doing this.

Step 1 is pulling the now very expensive yard ornament from the racecar. Practice makes perfect, Joel & I had the motor out and on the stand by lunchtime even starting late.

This is the fist size hole in the oil pan that let out all the smoke and caused the car to stop running.

Popping off the oil pan reveals an unattached connecting rod (or what's left of it) in #2 cylinder (middle of picture).

Further inspection reveals another hole in the side of the block itself. Plus lots of bits of debris everywhere. It wasn't a happy moment when the rod bearings seized. Hopefully the crank can be saved by the machine shop later.

The Head is going to need some work before it can play again. All those valves should be flush, not popping up like a game of Whack-A-Mole

Ok, we've set the scene, and parts are starting to trickle back from the machine shop. So its time to stop drinking beer and get to work.

One of the reliability modifications that was recommended was to cross-drill the crank. This means drilling another hole in the #2 and #3 rod bearing areas. Tests have shown that this balances out the oil flow to the rod bearings in a 944. The #2 rod bearing is notorious for failing due to low oil flow leading to the result shown in the pictures above. Here we see the new drilled holes in the crankshaft.

Since I'll never have this ease of access again, let's make the engine purty. The block (and other parts) came back reasonably clean from the machine shop, but far from perfect. I spent some time with a wire brush, picks and mineral thinner and cleaned out all the gunk in the corners and crevices. I then masked it - the red junk is Mobil1 cv joint grease to protect the seal area, the paint just wipes off afterwards - and hit it with a couple coats of high temp engine primer paint, followed by engine silver paint. This the back end of the motor where the flywheel and clutch live and soon will be buried deep in the bellhousing and won't be visible to anybody. But hey, good work is all in the details and I know it looks good in there. I'm sure the flywheel appreciates it also. I'd ask him, but he's hanging out in the bar with the intake manifold catching up on old times. They don't get together that much these days.

Next up is a picture of the crankshaft girdle (holds the crank to the case) with nice new main bearings being installed. You can see the holes to lubricate the center main bearing.

This is the Rear Main seal that prevents all the oil from pouring out from around the spining crankshaft. I had to use the 4" PVC Cap from the tubes that store my canopy poles in the racecar trailer, to tap the seal in evenly flush with the case. I then took a 3/4 inch extension and used that to tap the seal all into the back of the block. Its important to do this nice and slow as it really, really sucks if it starts leaking as you pretty much have to take the engine out again to fix it. We'll find out later how slow and methodical I was.

Just like the back of the block I'm painting the sides and front. Same routine with the picks and mineral spirits. Here's one of the primer coats being laid down.

For perspective, here's the "Before" picture of the oil cooler.

And here's it cleaned-up, painted and mounted.

The front of the block with the oil pump mounted on the crankshaft. Lots more stuff to come here. Belts, rollers, pullys, water pump, yada yada ... Hours and miles to go before I sleep.

some time later .... the f*3k%@! balance shafts are done - one in the upper right, the other one hiding behind the power steering bracket lower left - What should have a been an easy task turned out to be the major time sink so far. The damn things kept binding when the last two bolts were torqued to specs. Final solution was to load up the two bolts with Locktite, tighten until they start to bind, and back off. This is the only part of the process I'm worried about. Everything else is going together fine. The yellow water pump looks great! I'm sure it's worth 5-10 hp easily

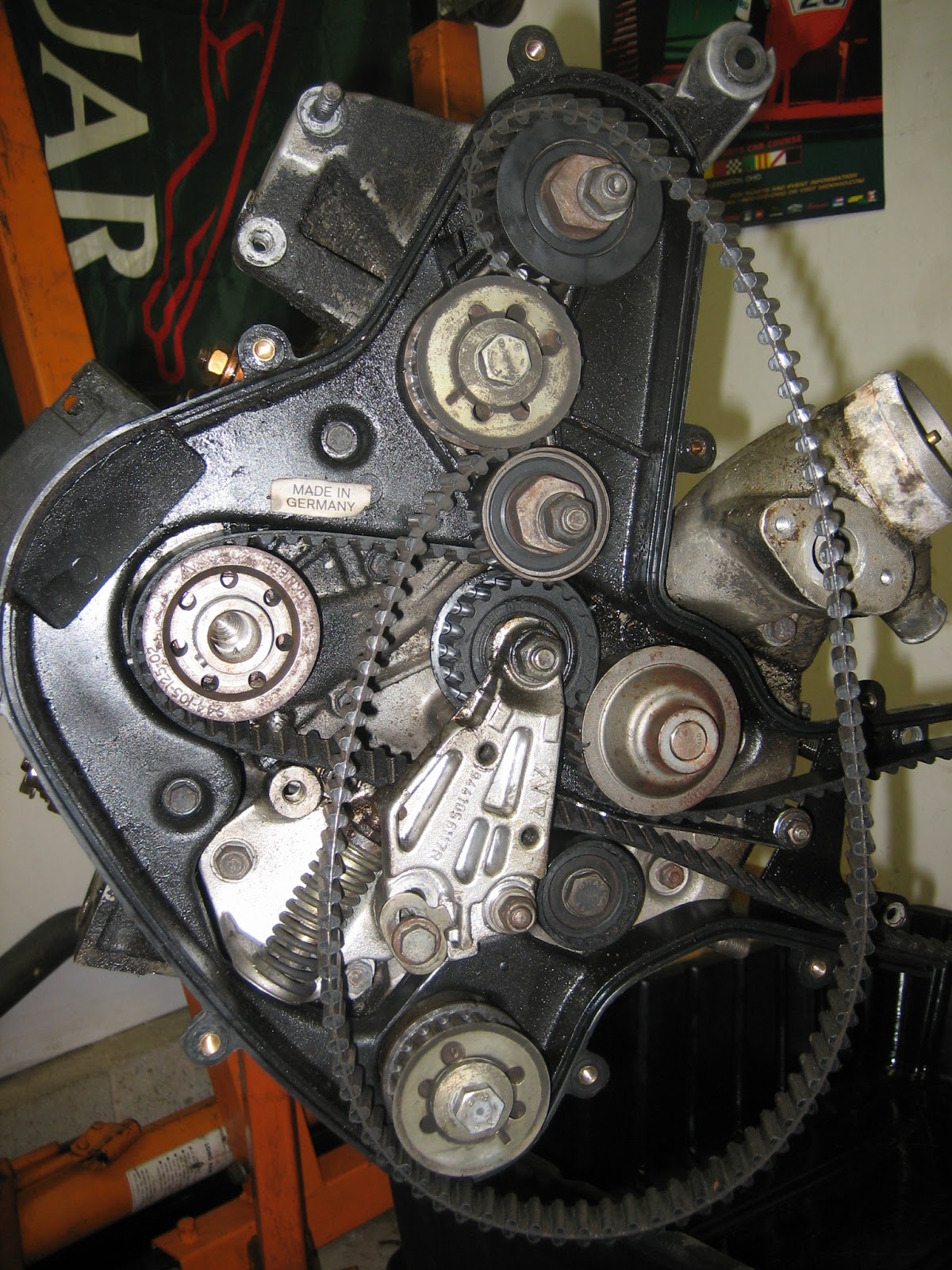

Told ya, lots-o-crap (that's a Porsche mechanic technical term) up front. Got you ya belts, (bling alert) crankshaft pulley, rollers, spring tensioners, etc. Busy area and still more to come.

Got the head back from the shop and slapped it on. Good news it didn't need any of those plutonium enhanced $$$$ valves. And proving that I'm teachable, this time I put in the oil reducing valve BEFORE I dump 6 qts of Mobil1 on my garage floor. I still may dump massive amount of fluids on the floor when I start it up, but it'll be from a NEW mistake.

Did some more modifications to the oil system to improve reliability - i.e. I don't want to rebuild this motor ever again - with the additions of the Lindsey Racing oil pan baffle kit. On the left is the oil pickup tube that sits in the oil pan with ring that has been welded on it to prevent oil from escaping on the sides. On the right is the hinged baffle that swings shut under loading in turns, preventing the oil pickup from sucking air when you're doing those massive tire smoking, 4 wheel drifting power slides .. oh sorry, I forgot we're talking about a 3000 lb, 150 hp Porsche 944 non-turbo, my bad. Anyway, it will help.

While waiting for the machine shop to finish up with the head, I took the time to wrap the exhaust headers to manage some of the heat under the hood. This is some kind of fiberglass, abestos wrap that insulates the pipes. It then gets sprayed down with a hi-temp silcon coating. Looks nice, compared to those nasty rusty headers from before.

And check that nice shiny oil pan hiding. Sweet! I'm going to have to start entering concours events.

My engine looked so nice and pristine, but now I have to go clutter it up with the wiring and hose junk. Can't be helped. Here the main wiring harness is starting to be routed, alternator is connected and some of the vacuum hoses are being attached.

And here we are in the middle of January. The signature Camtower has been attached, now I can get those oohs and ahhs when I pop the hood at the Dairy Queen - oh yeah, its not street legal so I can't drive it there ... but I can dream! - I have a short list now, finish the wiring, install the intake manifold, finish the vacuum lines, drop it off the engine stand, attach the clutch and bell housing and then pop it in the car. I can't wait.

2.7 Engine Rebuild (part 3)

Assembly is the reverse of Dis-assembly right? At least that's the conventional wisdom, but I'm not sold on that. You try making beer out of urine ....

Building a motor is a lot of work, so before we get started, let's take a break and take a look at why I'm (other than insanity) doing this.

Step 1 is pulling the now very expensive yard ornament from the racecar. Practice makes perfect, Joel & I had the motor out and on the stand by lunchtime even starting late.

This is the fist size hole in the oil pan that let out all the smoke and caused the car to stop running.

Popping off the oil pan reveals an unattached connecting rod (or what's left of it) in #2 cylinder (middle of picture).

Further inspection reveals another hole in the side of the block itself. Plus lots of bits of debris everywhere. It wasn't a happy moment when the rod bearings seized. Hopefully the crank can be saved by the machine shop later.

The Head is going to need some work before it can play again. All those valves should be flush, not popping up like a game of Whack-A-Mole

Ok, we've set the scene, and parts are starting to trickle back from the machine shop. So its time to stop drinking beer and get to work.

One of the reliability modifications that was recommended was to cross-drill the crank. This means drilling another hole in the #2 and #3 rod bearing areas. Tests have shown that this balances out the oil flow to the rod bearings in a 944. The #2 rod bearing is notorious for failing due to low oil flow leading to the result shown in the pictures above. Here we see the new drilled holes in the crankshaft.

Since I'll never have this ease of access again, let's make the engine purty. The block (and other parts) came back reasonably clean from the machine shop, but far from perfect. I spent some time with a wire brush, picks and mineral thinner and cleaned out all the gunk in the corners and crevices. I then masked it - the red junk is Mobil1 cv joint grease to protect the seal area, the paint just wipes off afterwards - and hit it with a couple coats of high temp engine primer paint, followed by engine silver paint. This the back end of the motor where the flywheel and clutch live and soon will be buried deep in the bellhousing and won't be visible to anybody. But hey, good work is all in the details and I know it looks good in there. I'm sure the flywheel appreciates it also. I'd ask him, but he's hanging out in the bar with the intake manifold catching up on old times. They don't get together that much these days.

Next up is a picture of the crankshaft girdle (holds the crank to the case) with nice new main bearings being installed. You can see the holes to lubricate the center main bearing.

This is the Rear Main seal that prevents all the oil from pouring out from around the spining crankshaft. I had to use the 4" PVC Cap from the tubes that store my canopy poles in the racecar trailer, to tap the seal in evenly flush with the case. I then took a 3/4 inch extension and used that to tap the seal all into the back of the block. Its important to do this nice and slow as it really, really sucks if it starts leaking as you pretty much have to take the engine out again to fix it. We'll find out later how slow and methodical I was.

Just like the back of the block I'm painting the sides and front. Same routine with the picks and mineral spirits. Here's one of the primer coats being laid down.

For perspective, here's the "Before" picture of the oil cooler.

And here's it cleaned-up, painted and mounted.

The front of the block with the oil pump mounted on the crankshaft. Lots more stuff to come here. Belts, rollers, pullys, water pump, yada yada ... Hours and miles to go before I sleep.

some time later .... the f*3k%@! balance shafts are done - one in the upper right, the other one hiding behind the power steering bracket lower left - What should have a been an easy task turned out to be the major time sink so far. The damn things kept binding when the last two bolts were torqued to specs. Final solution was to load up the two bolts with Locktite, tighten until they start to bind, and back off. This is the only part of the process I'm worried about. Everything else is going together fine. The yellow water pump looks great! I'm sure it's worth 5-10 hp easily

Told ya, lots-o-crap (that's a Porsche mechanic technical term) up front. Got you ya belts, (bling alert) crankshaft pulley, rollers, spring tensioners, etc. Busy area and still more to come.

Got the head back from the shop and slapped it on. Good news it didn't need any of those plutonium enhanced $$$$ valves. And proving that I'm teachable, this time I put in the oil reducing valve BEFORE I dump 6 qts of Mobil1 on my garage floor. I still may dump massive amount of fluids on the floor when I start it up, but it'll be from a NEW mistake.

Did some more modifications to the oil system to improve reliability - i.e. I don't want to rebuild this motor ever again - with the additions of the Lindsey Racing oil pan baffle kit. On the left is the oil pickup tube that sits in the oil pan with ring that has been welded on it to prevent oil from escaping on the sides. On the right is the hinged baffle that swings shut under loading in turns, preventing the oil pickup from sucking air when you're doing those massive tire smoking, 4 wheel drifting power slides .. oh sorry, I forgot we're talking about a 3000 lb, 150 hp Porsche 944 non-turbo, my bad. Anyway, it will help.

While waiting for the machine shop to finish up with the head, I took the time to wrap the exhaust headers to manage some of the heat under the hood. This is some kind of fiberglass, abestos wrap that insulates the pipes. It then gets sprayed down with a hi-temp silcon coating. Looks nice, compared to those nasty rusty headers from before.

And check that nice shiny oil pan hiding. Sweet! I'm going to have to start entering concours events.

My engine looked so nice and pristine, but now I have to go clutter it up with the wiring and hose junk. Can't be helped. Here the main wiring harness is starting to be routed, alternator is connected and some of the vacuum hoses are being attached.

And here we are in the middle of January. The signature Camtower has been attached, now I can get those oohs and ahhs when I pop the hood at the Dairy Queen - oh yeah, its not street legal so I can't drive it there ... but I can dream! - I have a short list now, finish the wiring, install the intake manifold, finish the vacuum lines, drop it off the engine stand, attach the clutch and bell housing and then pop it in the car. I can't wait.

944 Racecar - 1st Engine Rebuild (part 2) Winter 2007-2008

The web server holding my earliest postings into an uncaring universe quietly expired a while ago. Rather than replacing it, I'm posting the content so it will live on forever in the cloud, polluting my little corner of it. Enjoy.

2.7 Engine Rebuild (part 2)

Where were we? Oh yeah, pulling greasy crap off and putting it in a bucket. This is how its done down in Charlotte at the NASCAR shops right?

Here's the front of the motor. That sticker says "Made in Germany", so this must be a precision instrument.

A short while (and a few beers) later... belts and rollers gone, spring tensioner gone

Right side of the motor, practially nude. Oil pump gone, balance shaft cover gone (balance shaft shown in place just in case I forget where to replace it) Side of the motor clean enough to eat off of ... maybe not.

Here's an example on how I plan on putting the motor back. EVERY time I take something off, I take a picture, usually including my fat finger pointing at something of interest. Here I'm getting ready to pull the oil pump, so I'm pointing out to my future self Self, note there a washer AND a small round green seal here. Don't forget the seal!

You'll also notice the fine concours quality of the engine in this close-up. This is after 2 cans of engine degreaser and a wash down. That's why everything is going to the machine shop, for a good dunking in their acid bath.

Here's the bottom of the block with the crankshaft girdle removed. Starting to smell the horse in the barn or some such folksy American turn of phrase.

I'm starting to feel like a real race shop, I've got boxes of crap now.

The only thing left in the block is the crank. And it's days are numbered

Told ya!

The Naked Block in all its glory. Note the fine aged patina. Ah 89, that was a good year.

Everybody likes pictures, so here's another view. Naked cylinders, ooohhh.

This is another part of my master plan on having a motor that works when I'm done:

I put all the nuts and bolts, washers, gears, etc in plastic bags with a note inside. So when I go to bolt the oil pump back on, I know where the 46 bolts ( 5 different sizes) are. This method worked with my head gasket repair, so that's my story and I'm sticking to it.

So everything's apart. Lots of things are at the machine shop. The head and valves to be inspected and cleaned; block to be cleaned and bore diameters to be checked; pistons to be clean, inspected and rings replaced if needed. Crankshaft is having #2 & #3 rod areas cross-drilled to keep the rod bearings happy and balanced. Oil pan is having the Lindsey Racing baffle welded in - also to keep the rod bearings happy. Unhappy rod bearings = my race motor (see earlier pictures). And everything is taking a much needed bath

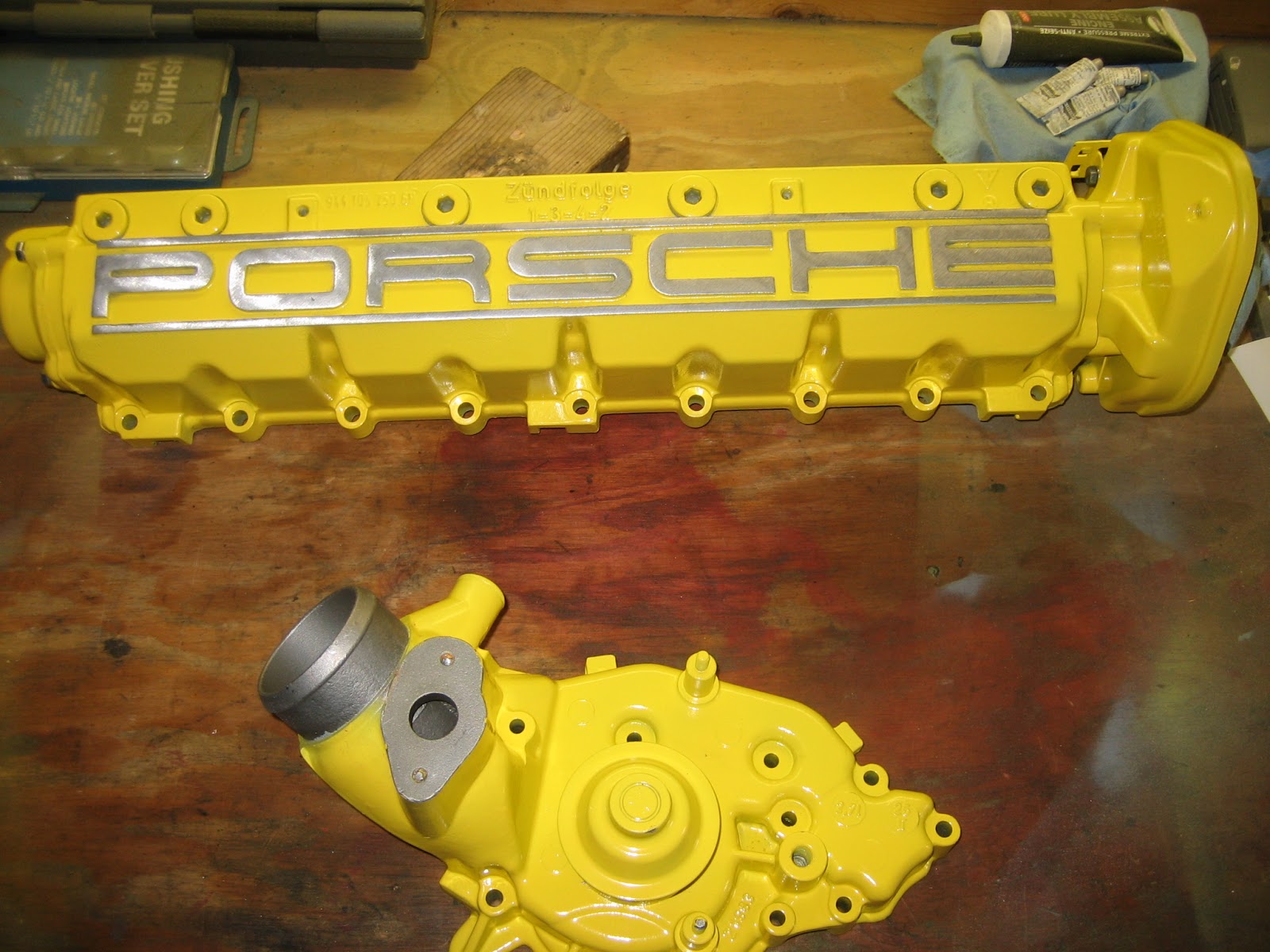

But you know what they say about idle hands .. since I'm waiting for machine shop I decided to provide some 'bling' to my motor, so I won't be embarrassed when I pop the hood at the local Porsche club events

My unsuspecting victim was the cam tower. And while I was in the middle of my blingfest my new waterpump innocently entered the Alpine garage. Too bad for it.

Assembly is the reverse of Dis-assembly right? More to come ...

2.7 Engine Rebuild (part 2)

Where were we? Oh yeah, pulling greasy crap off and putting it in a bucket. This is how its done down in Charlotte at the NASCAR shops right?

Here's the front of the motor. That sticker says "Made in Germany", so this must be a precision instrument.

A short while (and a few beers) later... belts and rollers gone, spring tensioner gone

Right side of the motor, practially nude. Oil pump gone, balance shaft cover gone (balance shaft shown in place just in case I forget where to replace it) Side of the motor clean enough to eat off of ... maybe not.

Here's an example on how I plan on putting the motor back. EVERY time I take something off, I take a picture, usually including my fat finger pointing at something of interest. Here I'm getting ready to pull the oil pump, so I'm pointing out to my future self Self, note there a washer AND a small round green seal here. Don't forget the seal!

You'll also notice the fine concours quality of the engine in this close-up. This is after 2 cans of engine degreaser and a wash down. That's why everything is going to the machine shop, for a good dunking in their acid bath.

Here's the bottom of the block with the crankshaft girdle removed. Starting to smell the horse in the barn or some such folksy American turn of phrase.

I'm starting to feel like a real race shop, I've got boxes of crap now.

The only thing left in the block is the crank. And it's days are numbered

Told ya!

The Naked Block in all its glory. Note the fine aged patina. Ah 89, that was a good year.

Everybody likes pictures, so here's another view. Naked cylinders, ooohhh.

This is another part of my master plan on having a motor that works when I'm done:

I put all the nuts and bolts, washers, gears, etc in plastic bags with a note inside. So when I go to bolt the oil pump back on, I know where the 46 bolts ( 5 different sizes) are. This method worked with my head gasket repair, so that's my story and I'm sticking to it.

So everything's apart. Lots of things are at the machine shop. The head and valves to be inspected and cleaned; block to be cleaned and bore diameters to be checked; pistons to be clean, inspected and rings replaced if needed. Crankshaft is having #2 & #3 rod areas cross-drilled to keep the rod bearings happy and balanced. Oil pan is having the Lindsey Racing baffle welded in - also to keep the rod bearings happy. Unhappy rod bearings = my race motor (see earlier pictures). And everything is taking a much needed bath

But you know what they say about idle hands .. since I'm waiting for machine shop I decided to provide some 'bling' to my motor, so I won't be embarrassed when I pop the hood at the local Porsche club events

My unsuspecting victim was the cam tower. And while I was in the middle of my blingfest my new waterpump innocently entered the Alpine garage. Too bad for it.

Assembly is the reverse of Dis-assembly right? More to come ...

944 Racecar - 1st Engine Rebuild - Winter 2007-2008

The web server holding my earliest postings into an uncaring universe quietly expired a while ago. Rather than replacing it, I'm posting the content so it will live on forever in the cloud, polluting my little corner of it. Enjoy.

2.7 Engine Rebuild

Well after a perfect week at the NASA Nationals, we had this little incident at Summit Point ...

After the race we find this, a part of a connecting rod lying on top of the engine cross member, and a nice size hole in the oil pan.

Ok, since the chances are good that the motor is seriously f'ked up, let go find another one, one that still has all the smoke inside it and plug that one into the racecar. We can worry about the bad motor at another time. That means it's off to the Internet, and in this case, Craigslist. I found an 89 944 (the only year with the 2.7L motor) up in Connecticut. Car had 150K miles on it, original (very flat) motor mounts and a hefty layer of grease, smudge, grime and grit finely layered over the entire engine compartment. But the motor ran and had good compression on each cylinder. After enumerating all the service work $$$ the car needed (belts & rollers, motor mounts, gaskets galore, etc) - it helps to have a certified Porsche Dealer Chief Mechanic (aka Gregg Wilson) with you for authority - the seller parted with the car for $1900 and it was loaded into the trailer for the ride home.

Follow me into my journey rebuilding the engine. This is a first for me, my previous deepest dive into mechanics was the replacing of my head gasket as chronicled earlier. This will be heavy on the pictures and light on the prose (I know my audience) so you have a fair chance of coming back sane. Me, I've already crossed that boundary ...

Step 1: remove engine from car *

* required: engine hoist, gullible friends with mechanical skills: Hey Joel, want to come by and drink some beer?

Would you believe our government trusts this guy to fly $50+ million dollar aircraft? I guess I'll let him work on my donor car ... Joel W, C5 pilot, Porsche buff, PO of the original racecar and owner of way too many tools. Sane? You be the judge.

We dropped the engine with the suspension still attached. It made life a lot easier.

We unbolted the engine and put the suspension and crossmember back into the car so it could be pushed into the back yard. The engine, in all its shiny glory, gets mounted on an engine stand.

This is what I found when I pulled the intake manifold. If you look closer,that's peanut shells. We're only part way done disassembling this. Maybe I'll find the squirel and his family later.

Front of the engine. When I asked the PO when was the timing belts were last done, the answer was: Well I did change the oil and put new tires on it last year. Okay ....

Top end is totally off. Yup, that the tops of the pistons. See the little cutouts in the top. That's so the valves don't contact the piston - aka A Bad Thing - Ask any racer to show you his bent valves collection. On second thought, only do that if you are a) bored out of your skull or b) have no life.

Cam Tower and Head ready to go to the machine shop

Bottom of the motor with the oil pan removed. You can see the oil intake (round object with screen) on the left, and the crankshaft lobes. You can see on the fourth one from the left, where it has been drilled to balance it.

Pistons, connecting rods and rod bearings on display. The bottom part of one of the con rods is what we saw earlier that went through the oil pan on the racecar. Chances are the Infamous #2 rod bearing seized,causing havoc.

The pile of parts for the machine shop grows larger.

We're not finished yet, we haven't found that squirrel yet!

2.7 Engine Rebuild

Well after a perfect week at the NASA Nationals, we had this little incident at Summit Point ...

After the race we find this, a part of a connecting rod lying on top of the engine cross member, and a nice size hole in the oil pan.

|

Ok, since the chances are good that the motor is seriously f'ked up, let go find another one, one that still has all the smoke inside it and plug that one into the racecar. We can worry about the bad motor at another time. That means it's off to the Internet, and in this case, Craigslist. I found an 89 944 (the only year with the 2.7L motor) up in Connecticut. Car had 150K miles on it, original (very flat) motor mounts and a hefty layer of grease, smudge, grime and grit finely layered over the entire engine compartment. But the motor ran and had good compression on each cylinder. After enumerating all the service work $$$ the car needed (belts & rollers, motor mounts, gaskets galore, etc) - it helps to have a certified Porsche Dealer Chief Mechanic (aka Gregg Wilson) with you for authority - the seller parted with the car for $1900 and it was loaded into the trailer for the ride home.

Follow me into my journey rebuilding the engine. This is a first for me, my previous deepest dive into mechanics was the replacing of my head gasket as chronicled earlier. This will be heavy on the pictures and light on the prose (I know my audience) so you have a fair chance of coming back sane. Me, I've already crossed that boundary ...

Step 1: remove engine from car *

* required: engine hoist, gullible friends with mechanical skills: Hey Joel, want to come by and drink some beer?

Would you believe our government trusts this guy to fly $50+ million dollar aircraft? I guess I'll let him work on my donor car ... Joel W, C5 pilot, Porsche buff, PO of the original racecar and owner of way too many tools. Sane? You be the judge.

We dropped the engine with the suspension still attached. It made life a lot easier.

We unbolted the engine and put the suspension and crossmember back into the car so it could be pushed into the back yard. The engine, in all its shiny glory, gets mounted on an engine stand.

This is what I found when I pulled the intake manifold. If you look closer,that's peanut shells. We're only part way done disassembling this. Maybe I'll find the squirel and his family later.

Front of the engine. When I asked the PO when was the timing belts were last done, the answer was: Well I did change the oil and put new tires on it last year. Okay ....

Top end is totally off. Yup, that the tops of the pistons. See the little cutouts in the top. That's so the valves don't contact the piston - aka A Bad Thing - Ask any racer to show you his bent valves collection. On second thought, only do that if you are a) bored out of your skull or b) have no life.

Cam Tower and Head ready to go to the machine shop

Bottom of the motor with the oil pan removed. You can see the oil intake (round object with screen) on the left, and the crankshaft lobes. You can see on the fourth one from the left, where it has been drilled to balance it.

Pistons, connecting rods and rod bearings on display. The bottom part of one of the con rods is what we saw earlier that went through the oil pan on the racecar. Chances are the Infamous #2 rod bearing seized,causing havoc.

The pile of parts for the machine shop grows larger.

We're not finished yet, we haven't found that squirrel yet!

Subscribe to:

Comments (Atom)

My (Premature) Obiturary

Lots of news organizations maintain pre-written obits so that when a celebrity passes, they open up the file and need to just update a few l...

-

Other than making zoom-zoom noises I'm a pretty useless motor When we last left off, I was young, full of unwarranted optimism, eager ...

-

Hanging out in a Yurt in Tibet with the Golok nomads. Drinking Barley Tea, heated by burning dried yak turds. Some temple details. This wa...

-

The racecar is just about ready for the season. Next up for it is a corner balance and alignment. I can do the corner balancing, but alignme...

.jpg)